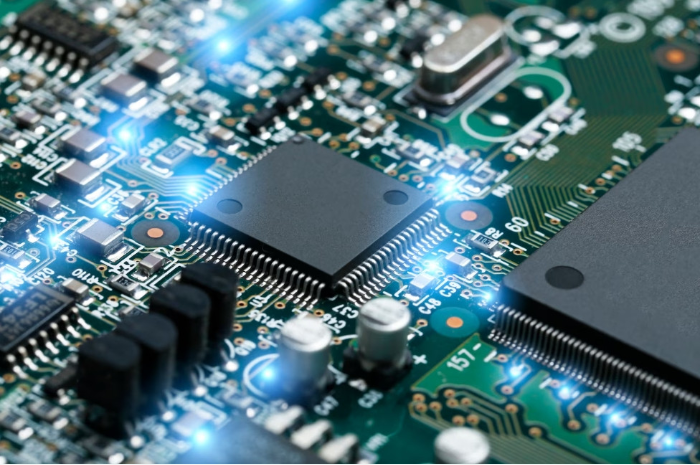

The Close Connection Between ICs and Everyday Life

Semiconductor manufacturing is a complex and vital technology that plays a key role in the modern electronics industry. The smartphones, computers, and other devices we use every day are composed of multiple IC chips with different functions. Taiwan’s well-established semiconductor supply chain has laid a solid foundation for its position as a global semiconductor powerhouse.

Wafer Frames with High-Precision Requirements

Wafer frames are critical components in semiconductor processes. They are typically made from high-quality stainless steel, requiring flat surfaces and precise dimensions. Their primary function is to support and protect the wafer throughout various stages of processing. As wafer fabrication is highly complex, it demands precise technologies and equipment to ensure process integrity.

The stainless steel wafer frames manufactured by YJ Stainless meet specifications for a wide range of equipment. We offer customizable surface treatments, including polished and matte finishes, laser engraving, groove etching, and notch processing. Each frame undergoes tension testing to minimize deformation or loss during Blue Tape removal stages.

Critical Carriers for Wafer Handling

Wafer carriers are tools used to transport and handle wafers during semiconductor manufacturing. They are typically made of specialized materials to prevent damage throughout the process. For front-end processing, carrier design must accommodate exposure to heat baking, chemicals, and other process conditions to ensure safe and efficient wafer handling.

YJ Stainless offers one-stop procurement with extended development of peripheral products. Our wafer carriers are made from lightweight extruded aluminum (6061/6063) with anodized surfaces to enhance ESD resistance and prevent wafer contamination. We offer multiple sizes including 6″, 8″, and 12″ options.

Key Technologies Fueling Greater Innovation

In conclusion, wafer frames and carriers are essential to semiconductor manufacturing. Their precision design and construction ensure that components perform with high reliability and efficiency. Continued innovation in these technologies will further drive semiconductor advancement, paving the way for more powerful, next-generation electronic devices.