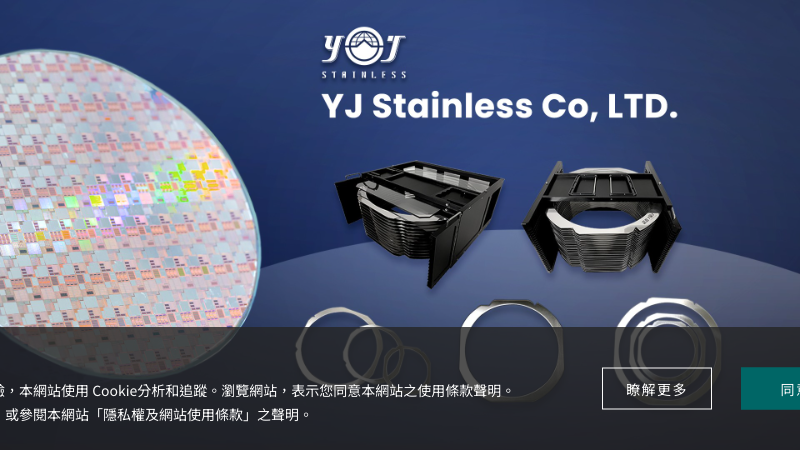

Essential Tools in Semiconductor Manufacturing: Wafer Carriers, Wafer Shipping Boxes, and Wafer Frame Boxes

In the high-precision world of semiconductor manufacturing, the importance of specialized tools like wafer carriers, wafer shipping boxes, and wafer frame boxes cannot be overstated. These tools play a crucial role in protecting delicate semiconductor wafers throughout various stages of production, transport, and storage. Let’s delve deeper into the features and applications of these essential components.

Wafer Carriers: Ensuring Safety and Integrity

Wafer carriers, also known as wafer cassettes, are designed for the safe handling and storage of semiconductor wafers. Made from durable materials like polypropylene or PFA (Perfluoroalkoxy), these carriers offer resilience against potential damage and contamination.

They are tailored to fit different wafer sizes, ranging from 125 mm to 200 mm, and can be customized for specific requirements.

Detailed Features:

Antistatic Properties: Essential in cleanroom environments, many wafer carriers are constructed to prevent static damage.

Design Elements: The carriers feature designs that minimize wafer contact, such as conical bases or V-shaped grooves, significantly reducing the risk of damage.

Visibility and Thermal Stability: Some carriers are transparent for easy inspection, and materials like glass and quartz offer excellent thermal stability for high-temperature processes.

Wafer Shipping Boxes: Secure Transportation Solutions

Wafer shipping boxes are integral to the safe transport of wafers between different manufacturing processes. These boxes are crafted with anti-static materials and are specifically designed to be lightweight yet durable.

Their structural reinforcement ensures longevity, making them a reliable choice for transporting semiconductor wafers.

In-Depth Insights:

Customization Options: These shipping boxes can be customized in size and capacity to accommodate various wafer sizes, enhancing their utility in the semiconductor industry.

Wafer Frame Boxes: Advanced Protection and Handling

Wafer frame boxes serve a similar yet distinct purpose, focusing on protecting wafers during transfer between manufacturing stages. These boxes stand out for their isolation capabilities, ensuring wafers are securely protected from potential damage during transportation.

Additional Features:

Laser Engraving and RFID: Advanced customization options like laser engraving and RFID installation are available for enhanced tracking and identification.

In conclusion, wafer carriers, wafer shipping boxes, and wafer frame boxes are pivotal in maintaining the quality and integrity of semiconductor wafers.

Their specialized designs, material choices, and customizable features make them indispensable in the semiconductor industry, ensuring that the delicate wafers remain intact and uncontaminated from production to packaging.